If you’re in manufacturing, there’s no escaping the buzz around extended reality (XR) technology and its immense potential to streamline operations. But is the hype truly justified? New research emphatically confirms XR is already delivering game-changing impacts – and will likely become an industry mainstay.

The 2024 study The State of Extended Reality (XR) in Manufacturing surveyed 400 manufacturing professionals across the United States, spanning industries from automotive to electronics to energy production. The findings shed light on XR’s rapid growth trajectory and the tangible value-adds companies are realizing today.

Widespread XR Adoption Underway

Perhaps the biggest eye-opener is that the adoption of cutting-edge solutions like augmented reality (AR), virtual reality (VR), and mixed reality (MR) is now mainstream. Exactly half of the surveyed manufacturers currently utilize XR in some capacity.

For those already using XR, the benefits have been plentiful and clear. A full 75% of these manufacturers reported seeing a tangible return on their XR investments so far. The gains have come in several areas critical to productivity and profitability.

Quantifiable Business Impacts Driving XR Growth

What exactly is propelling this accelerated XR embrace? The bottom-line benefits manufacturers already enjoy tell a compelling story:

- 49% have reduced material waste and scrap

- 48% have accelerated production cycle times

- 45% have lowered operational expenditures

- A remarkable 95% report a safer workforce after XR simulation training

With value propositions like those, it’s no surprise that 75% of XR users have realized a clear ROI – and 40% foresee critical functions like inventory management becoming XR-driven within 10 years.

Current XR Use Cases Delivering Results

So how exactly are manufacturers applying XR solutions to move the needle? According to the survey, the most popular use cases include:

- Training: Named as the top application by 51% of XR users, immersive VR training provides experiential upskilling that boosts workforce capabilities. Realistic machine operation and hazardous environment simulations enhance long-term retention while mitigating safety risks from real-world practice sessions.

Our AR Training Solutions ensure employees master complex equipment and procedures through self-guided tutorials overlaying holographic visualizations.

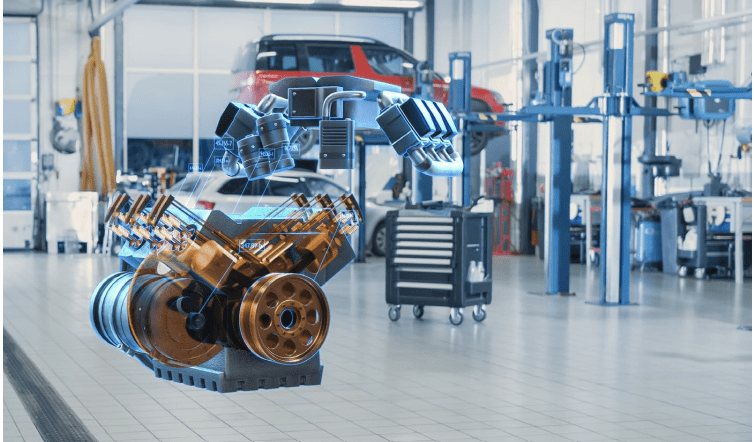

- Maintenance/Repair: 45% of XR adopters leverage AR for remote expert assistance, with technicians receiving overlaid guidance from off-site SMEs. VR simulations also provide risk-free training for high-stakes repair tasks.

With our VR Maintenance Training platform, users master mission-critical troubleshooting through hyper-realistic replicas of assets and environments.

- Design & Prototyping: By creating true-to-life VR models first, surveyed manufacturers streamline iteration cycles, minimize material waste, and accelerate time-to-market. 52% use XR for digital mock-ups that enable in-depth reviews and collaboration before physical builds.

Our Product Visualization Services help turn designs into immersive 3D models that users can manipulate in virtual space to perfect concepts.

- Quality Control: 45% of XR users deploy AR for quality inspections, overlaying reference data atop physical parts to quickly identify defects. Some use portable XR with thermal imaging to detect defective equipment.

The Future Growth of XR in Manufacturing

While XR is already providing concrete value, the most compelling data points to its future ubiquity across the manufacturing sector. Among the 49% of companies not currently utilizing XR, a majority have plans to adopt it within the next decade. Specifically:

- 59% intend to start using XR within the next 5 years

- An additional 19% have scheduled XR rollouts between 5-10 years from now

- Only 21% have not targeted dates for adoption

The window is closing for manufacturers to get ahead of the curve and start realizing XR’s transformative potential. Those who delay will likely face challenges being as efficient, safe, and cost-effective as competitors already enhancing their operations with XR.

Tackling Key XR Implementation Challenges

Despite the growing adoption, real barriers to XR integration still exist today according to surveyed manufacturers:

- Training Gaps: 89% of XR users said their workers initially felt uncomfortable with the technology. 31% even experienced misuse and equipment downtime from insufficient training – underscoring its importance.

Change Management Services are critical to fostering XR user acceptance and long-term enablement through role-based curriculums and hands-on coaching.

- Cost Concerns: Nearly half (46%) of non-users cited hardware and software pricing as a major hurdle.

Our XR Solution Packages provide a strategic mix of affordable, enterprise-grade tools tailored to specific use cases and roll-out plans – avoiding overbuying.

- Integration Headaches: Another 46% had hesitations about merging XR with existing workflows.

Our XR Solution Architects provide comprehensive deployment planning to seamlessly harmonize new XR capabilities into your operation’s unique realities.

- Security Risks: A quarter (25%) remained hesitant over data privacy and cybersecurity.

We partner with leading XR security firms to implement robust safeguards, ensuring intellectual property and sensitive information remains completely protected.

However, the survey also revealed that most of these perceived barriers are often smaller hurdles than anticipated. For example, over half (54%) of current XR users said their teams adapted quickly with only minimal training. On integration, 63% described the process as relatively seamless or just requiring minimal support.

The data clearly shows XR has crossed the chasm into mainstream manufacturing adoption. Those still watching from the sidelines need to strongly consider investing soon before falling irrevocably behind.

The Time is Now for XR in Manufacturing

The convergence of cost-efficient hardware, scalable software platforms, and proven services makes 2024 the perfect moment for manufacturers to explore XR’s transformative potential.

With widespread business gains of 45%+ cost savings, 50% waste reduction, 50% time savings, and near-universal improvements to safety and productivity on the table, can you afford to delay? No, why because the competitive advantages will only compound over time.

Manufacturers who kick-start their extended reality journeys now can start realizing the ROI and efficiency gains immediately. They’ll have a head start future-proofing their factories through virtual manufacturing techniques and data integration.

Let our XR/AR/VR solutions consultants guide your first step into the future of manufacturing. We’ll partner with you to navigate every stage of XR adoption:

- Comprehensive assessments to identify your highest-value XR use cases

- Cutting-edge tool selection to meet requirements while controlling costs

- Proven change management to cultivate XR mastery across your workforce

- Seamless integration services to merge XR with existing digital frameworks

- Pathway planning for long-term scaling as XR’s role inevitably expands

We have the expertise to ensure your implementation accelerates productivity, slashes waste, and elevates safety from day one. Check our Portfolio.

The future factory floor will be an immersive XR environment. Whether you want to gain a decisive competitive lead or simply avoid falling behind in the years ahead, we’re ready to guide your extended reality journey.

Embrace XR’s full potential today with our team. The manufacturing world is accelerating into an exciting new era – we’ll ensure your operation capitalizes every step of the way.

Facts and Figures’ Courtesy: The State of Extended Reality (XR) in Manufacturing by HTC VIVE Business